Gasket Plate Heat Exchanger

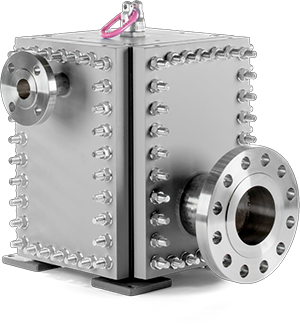

BLOC

Text 2

What is a Bloc ?

Plate Heat Exchanger with fully welded plate pack- Without any gaskets between the Heat Transfer Plates.

- Platepack is within a pressure vessel, consisting of 4 Columns…

- 2 Heads (Top Head, Bottom Head)

- 4 Panels.

- Gasketed with 4 Gaskets, with highest resistance against almost every fluid.

- Tightened with bolts/nuts and washers.

- Fully welded PHE

- Welded PHE without gaskets between the HE-Plates

- Bloc Type Heat Exchanger

Text 3

Applications for Bloc

Oil & Gas : Gas Dehydration、Gas Sweetening、Crude treatment

Oleo chmical : Vegetable oil processing、Oil extraction、Hexane Recovery、Refining

Refinery : Desalter、Product coolers、Product condensers、Alkylation、Heat recovery

Chemical : Chlor-Alkali、Caustic plant、Urea、Ammonia、Ammonium Nitrate、Fertilizer、Nitric acid

Petrochemical : Ethylene Oxide / Ethylene、Phenol、Bisphenol、Caprolactam、Glycol

Text 4

Bloc Model Overview

| FPB006 | FPB014 | FPB025 | FPB056 | FPB113 | FPB188 | ||

|---|---|---|---|---|---|---|---|

| Area DC1 | 1 - 8 | 8 - 35 | 27 - 82 | 61 - 184 | 123 - 368 | 306 - 613 | m2 |

| Area CE1 | 2 - 14 | 15 - 63 | 48 - 145 | 98 - 290 | 193 - 580 | 483 - 967 | m2 |

| Max. No. Moduls | 6 | 7 | 5 | 5 | 5 | 6 | - |

| Max. Pressure | 40 | 40 | 40 | 40 | 32 | 32 | barg |

| Max. Conection | DN 150 | DN 200 | DN 250 | DN 400 | DN 800 | DN 800 | - |

Text 5

Gaskets and Codes

Available gasket materials

| Type | Temperature, Pressure range | Remark |

|---|---|---|

| ePTFE | -50℃ to +150℃,FV-25 bar | Polytetrafluorethylene |

| Graphite | -50℃ to +400℃,FV-40 bar | Graphite with camprofil |

| Klingersil | -50℃ to +150℃,FV-25 bar | Aramid fibres with NBR binder |

Codes & Standards

| EN13445 & PED | Max. Design Pressure:FV / 40 barg |

|---|---|

| ASME VIII Div 1 & U-Stamp | |

| API662, NACEMR0175 & MR0103 | Max. Design Temperature:-50 / +400℃ |