Gasket Plate Heat Exchanger

Free-Flow Design

Text 2

Exclusive Free-Flow Design

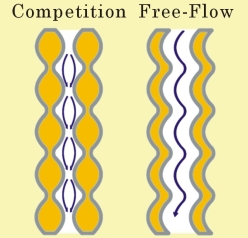

Competitive plate heat exchanger designs claim wide-gap advantages, but pinch points in their design can block flow and create slurry buildup. The Free-Flow's channels handle bigger particles and require less maintenancebecause they are of a constant width.

Text 3

FREE-FLOW PLATES

| FREE-FLOW CONNECTIONS AND PRESSURES | ||

|---|---|---|

| MODEL | STUDDED PORT SIZE*(in.) | OPERATING PRESSURES+ |

| AT161FF | 3 | up to 86 psig (6.9 bar)(6kg/cm2) |

| AT40FF | 4 | up to 150 psig (11.3 bar)(10.5kg/cm2) |

| AT184FF | 8 | up to 86 psig (6.9 bar)(6kg/cm2) |

| AT192FF | 12 | up to 86 psig(6.9 bar)(6kg/cm2) |

| MATERIALS OF CONSTRUCTION | |

|---|---|

| PLATES | GASKETS |

| T304 stainless steel | Nitrile (NBR) |

| T316 stainless steel | Ethylene Propylene Rubber (EPDM) |

| Titanium | Silicone |

| Avesta SMO 254 | Viton |

| Hastelloy | Butyl (Resin Cured) |

| Nickel | Hypalon |

| Incoloy | |