Feature ArticleIndustry Solutions :Semi-conductor Cooling

reads

Semiconductor production will include heating and cooling process fluids during its manufacturing process. In such highly sophisticated and complex operations, manufacturers need high performance thermal solutions that are cost effective and without risk of complications. Kaori specializes in customizing quality heat exchangers to be your trusted thermal solution in such demanding cases.

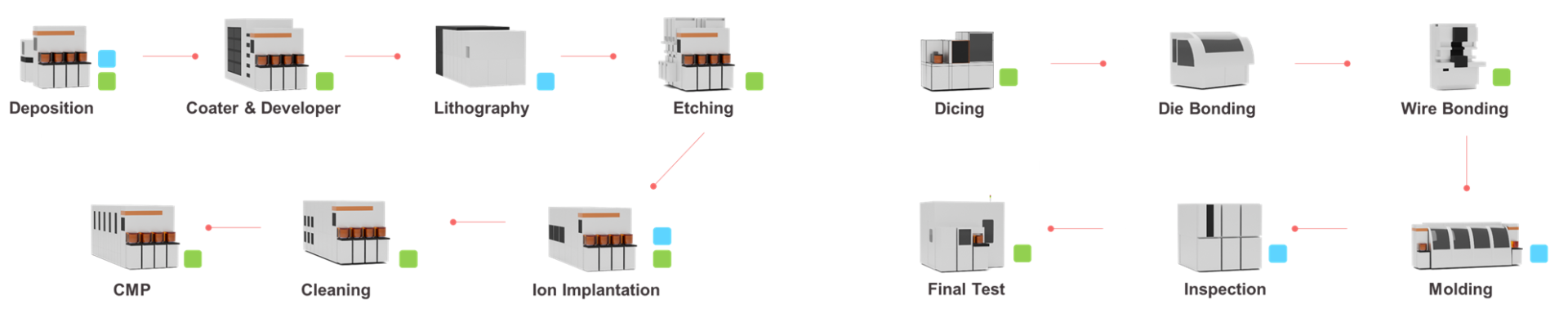

In front-end semiconductor manufacturing, each process step may serve a different function, but they all share one critical requirement — a stable and highly precise temperature control system.

During operation, process equipment generates a significant amount of heat that must be effectively removed. This is typically achieved through liquid-cooled process equipment, such as chiller systems. For processes that require vacuum or high-vacuum conditions (Gas Chiller applications), cryogenic or chilled vacuum pumps are utilized to ensure a stable and reliable process environment.

In these applications, brazed plate heat exchangers (BPHEs) deliver highly efficient, low-energy thermal solutions that enhance process performance and ensure long-term system reliability.

Brazed Plate Heat Exchangers in the Semiconductor Industry

Liquid-Cooled Process Equipment

Liquid-Cooled Process Equipment

Front-End Semiconductor Manufacturing Process | Back-End Semiconductor Manufacturing Process |

| |

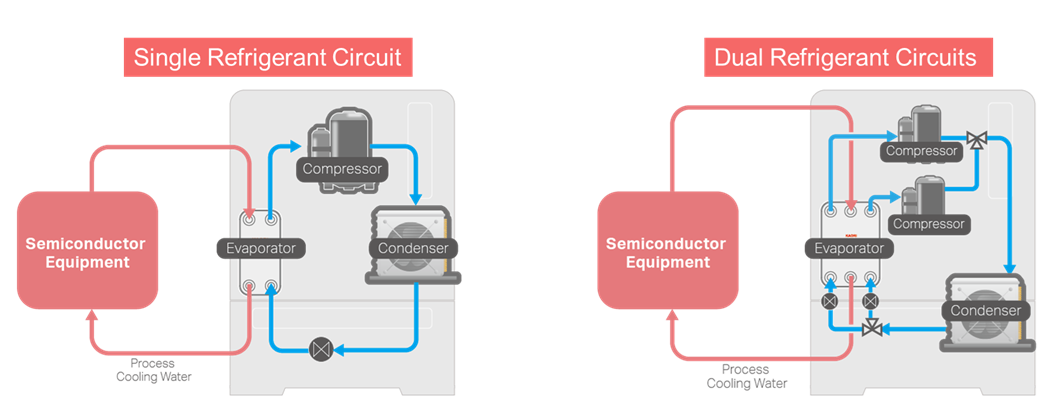

Brazed Plate Heat Exchangers in Air-Cooled Liquid Chillers

In air-cooled chiller systems, brazed plate heat exchangers (BPHEs) are commonly configured as evaporators. In addition to standard single-circuit designs, BPHEs can also support dual-compressor and dual-refrigerant circuit configurations.

With a single BPHE, the system can flexibly adapt to varying load conditions: operating with one compressor under low load and activating a second compressor as demand increases. This configuration not only ensures stable cooling capacity but also significantly improves energy efficiency.

|

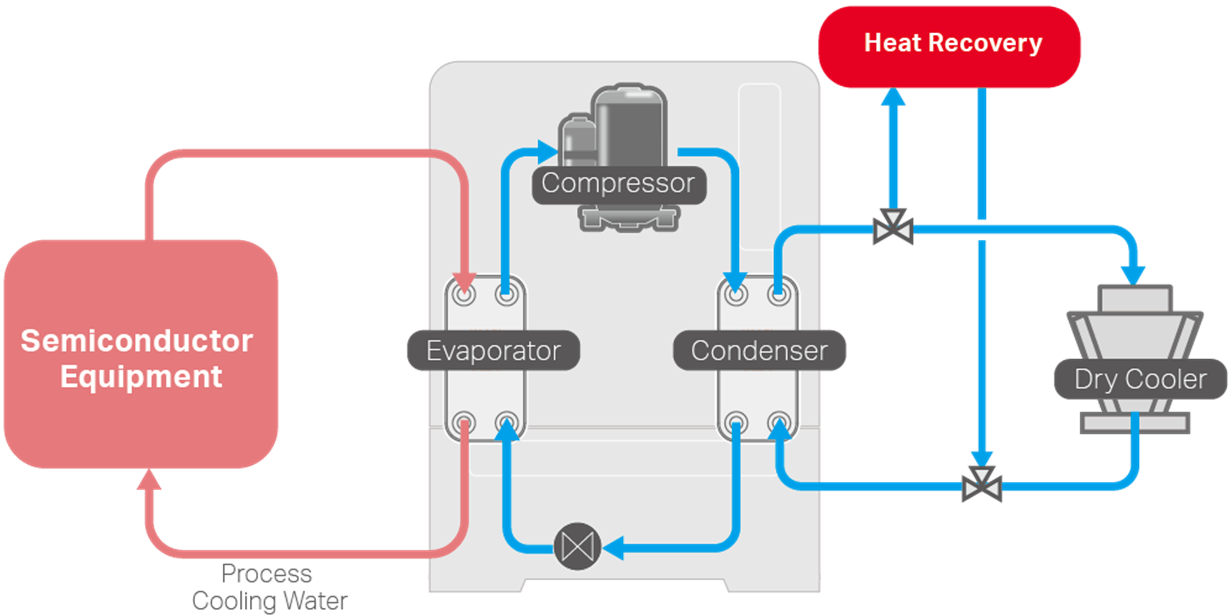

Brazed Plate Heat Exchangers in Water-Cooled Liquid Chillers

| In water-cooled chiller systems, brazed plate heat exchangers (BPHEs) can be flexibly configured as either evaporators or condensers, enabling highly efficient heat transfer within the system. The cooling water loop can dissipate process-generated heat directly to the environment via a dry cooler, effectively reducing system temperature. Additionally, BPHEs can be integrated with heat recovery systems to transfer excess thermal energy for use in processes such as cleaning or insulation, further enhancing energy efficiency and supporting sustainable manufacturing practices. |

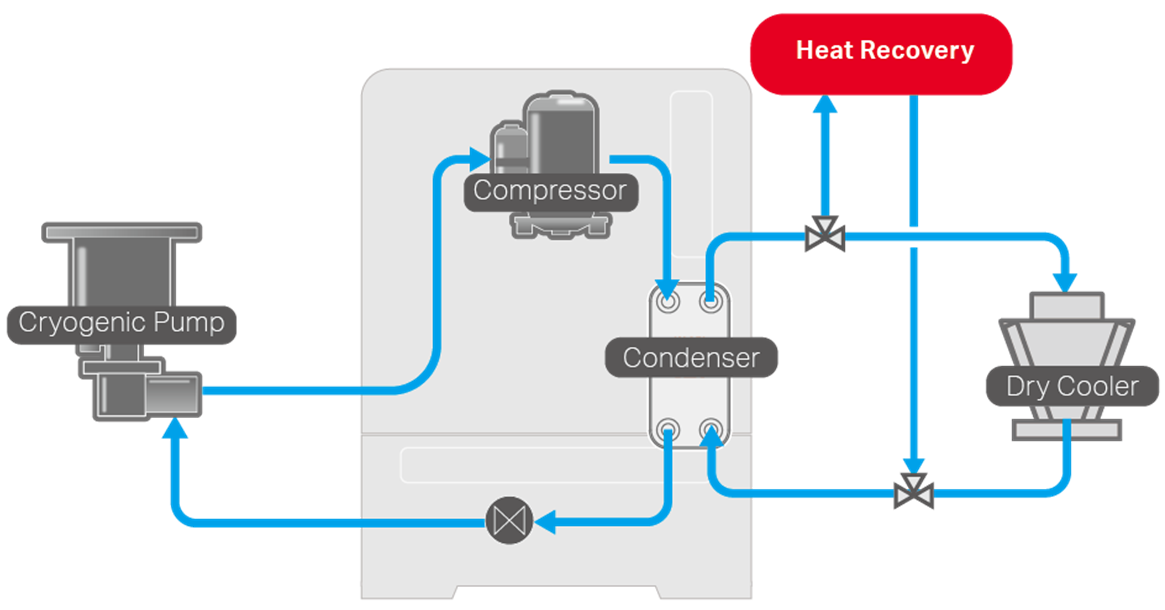

Brazed Plate Heat Exchangers in Cryogenic Pumps

In semiconductor manufacturing, cryogenic pumps are commonly used to create high or ultra-high vacuum environments, making them suitable for front-end processes such as CVD, PVD, and etching. These pumps operate using cooling media such as helium or nitrogen. BPHEs are typically employed for water-cooled heat dissipation, functioning as condensers. The heat can be rejected via a dry cooler or integrated with a heat recovery system, directing hot water back to other processes to enhance energy efficiency. |

|

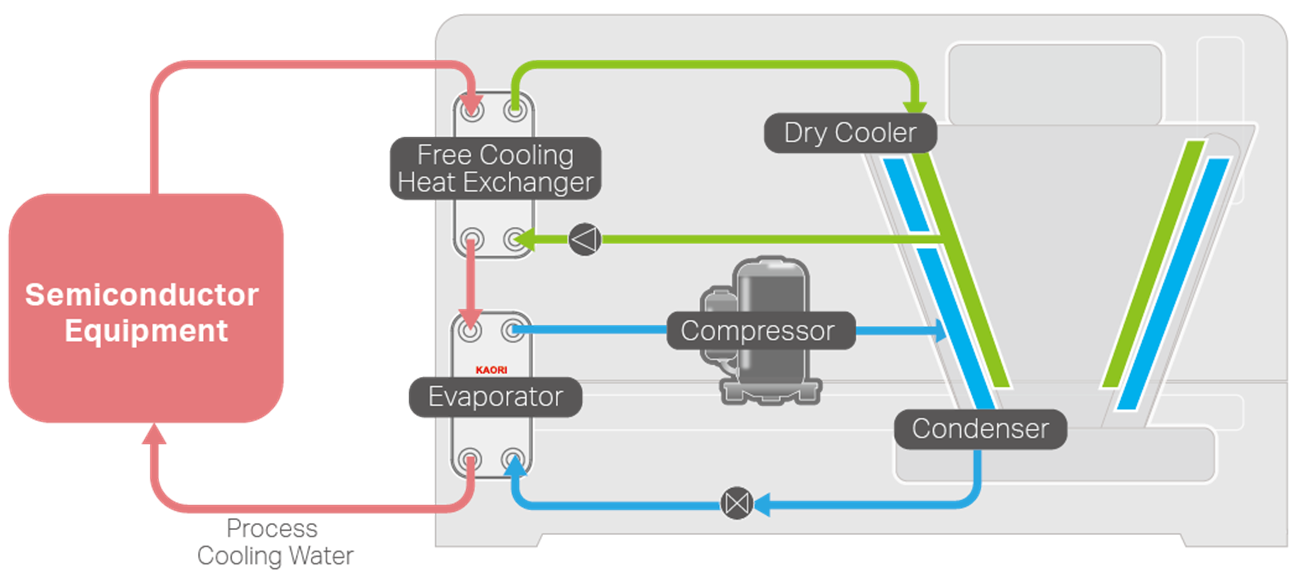

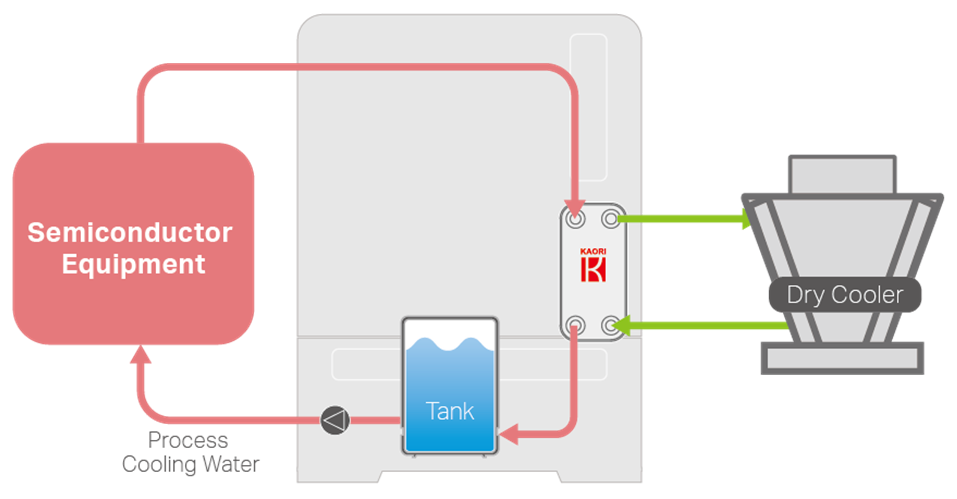

Brazed Plate Heat Exchangers in Free Cooling

| Free Cooling refers to a mode in which, when the ambient temperature is lower than the required cooling water temperature for the process, the compressors are not activated. Instead, outdoor cooling water or cold air is used directly for heat exchange. Under these conditions, the system can leverage BPHEs in combination with dry coolers and other equipment to utilize the low-temperature energy from the external environment for cooling. This significantly enhances the Seasonal Energy Efficiency Ratio (SEER), reflecting the system’s actual average efficiency throughout the year. (A higher SEER indicates more efficient energy usage and lower overall operating costs.) |

Brazed Plate Heat Exchangers in Hybrid Cooling Systems

Hybrid Cooling has become a key trend in advanced process cooling systems. By combining traditional air-cooled operation with Free Cooling mode, the system can automatically switch between modes based on ambient temperature and load requirements.

Compared to conventional designs, BPHEs offer a compact footprint and high thermal efficiency, allowing integration into a single chiller unit and flexible support for dual-mode operation, enabling energy-efficient and sustainable process cooling solutions. |

|

Reach Out to Us

Kaori team is ready to design a customized thermal management solution for your semiconductor operations. Contact us today to get started.