Feature ArticleCommon Reasons for Damages in BPHEs- (3) Freeze

reads

Brazed plate heat exchanger is formed with chevron plates and vacuum brazed with copper, it contains very compact and special structure. Two fluids can perform high efficiency heat exchange with very little temperature difference, it is also corrosion resistant, pressure resistant, compact, high efficient. It is widely used in HVAC, hydraulic cooling, heat recovery…etc., and acting as a very important role in energy saving and carbon emission reduction in major industries.

Brazed plate heat exchanger normally has long lifetime under suitable working conditions, however we still need to be cautious about the followings that may cause rare damages. Kaori’s BPHE team has more than 30 years of experience in helping system designers and users to use BPHE properly, so the lifetime is maximized, making it economical and satisfactory for customers.

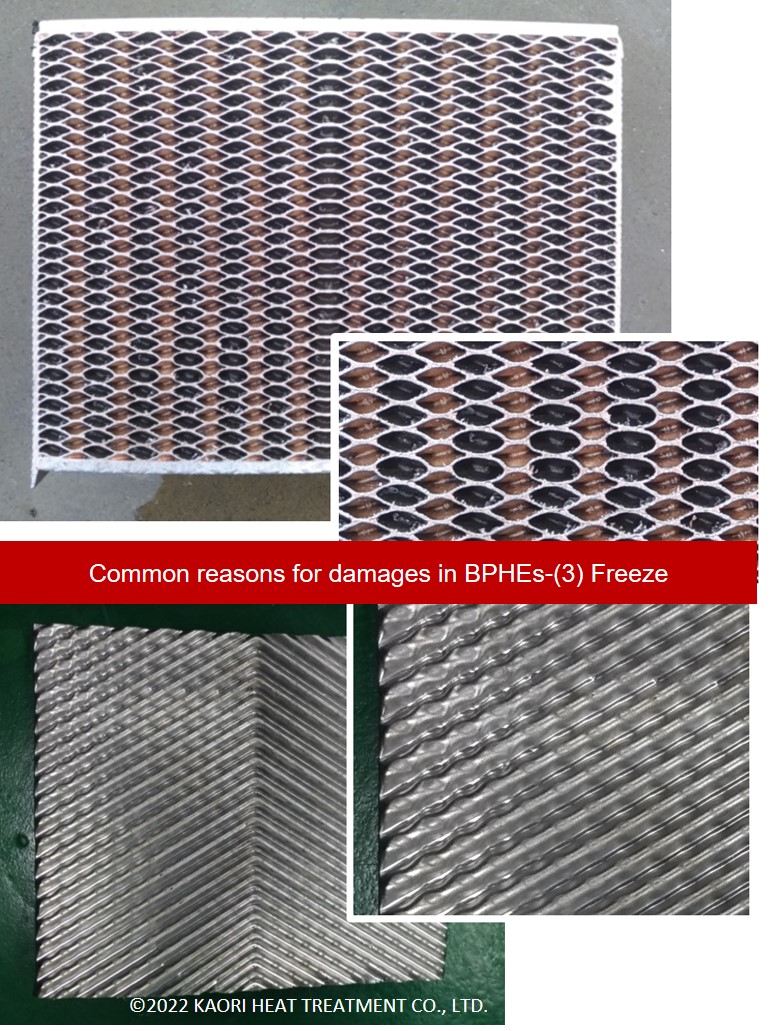

Freeze

Common characteristics

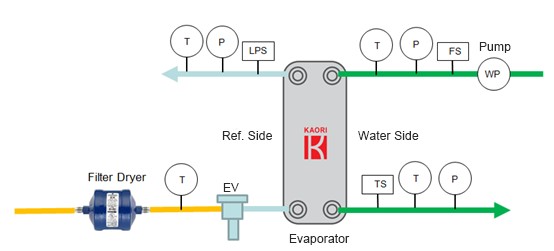

- Commonly spotted on the water side of chiller, and heat pump.

- Common early phenomenon: Drop in evaporation temperature, increase in water side pressure drop, increase temperature difference between water inlet and outlet, and decrease in water flow rate.

- Other phenomenon: Abnormal in system (shut down in low pressure switch, shut down due to anti-freeze protection), deformation in heat exchanger, internal leakage due to freeze.

Possible cause

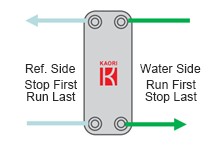

- Improper shut down procedure (the correct process as shown below)

- Insufficient water flow or congestion in flow channel (Failure in flow switch or filter)

- Failure in refrigerant low pressure switch or related anti-freeze mechanism

- Low concentration of brine, causing high freezing point.