Feature ArticleBrazed Plate Heat Exchanger Applications in Immersion Cooling

reads

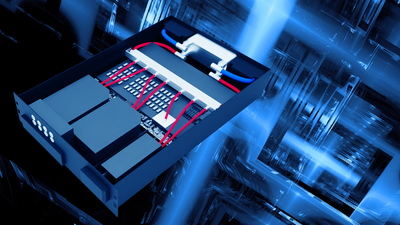

Immersion cooling is an advanced thermal management solution that submerges servers and IT equipment directly into electrically non-conductive coolant.

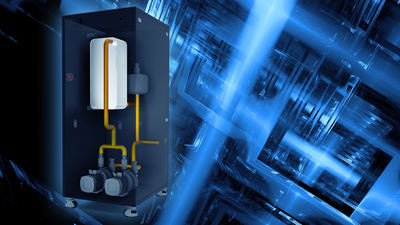

Introduction to Immersion Cooling in Data CentersThis liquid efficiently absorbs and removes heat, significantly reducing operating temperatures and energy consumption. Compared to traditional air-cooling systems, immersion cooling minimizes the need for fans and air conditioning, improves PUE, and extends equipment lifespan. It is especially suited for high-density deployments, high-performance computing (HPC), and AI workloads, making it an ideal technology for sustainable and energy-efficient data centers. |  |

Brazed Plate Heat Exchanger Applications in Immersion Cooling

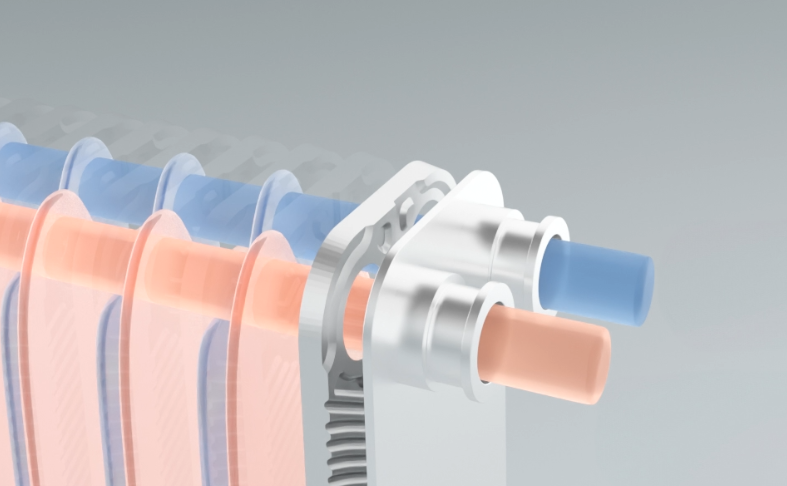

KAORI offers complete heat exchanger solutions for both precise air conditioning systems and immersion cooling systems. In Immersion Cooling CDUs (Cooling Distribution Units), Brazed Plate Heat Exchangers (BPHEs) play a central role. They enable efficient heat transfer, moving heat from the immersion loop to chilled water or external cooling systems, supporting thermal loads of 30-200kW+ and enabling lower PUE operations. The connectors and plates of KAORI's BPHE products are made of stainless steel, with 99.9% pure copper used as the brazing material. The maximum working pressure of the products can reach 30 bar (up to 140 bar upon request), with a maximum working temperature of 200 °C , and they are CE(PED) / UL certified.

Compatibility with Dielectric Fluids and Cooling WaterThe core of immersion cooling technology lies in using various dielectric fluids to directly cool servers for highly efficient heat dissipation. KAORI BPHEs possess exceptional material compatibility, stably interacting with commonly used single-phase (e.g., mineral oil, synthetic oil) and two-phase (e.g., fluorinated fluids) dielectric cooling liquids on the market. This ensures the heat exchanger maintains its high performance and long-term stability across different fluid environments. Concurrently, on the secondary cooling loop (i.e., facility side), KAORI BPHEs can also seamlessly integrate with chilled water, dry cooler loops, or other external cooling systems. This broad compatibility provides great flexibility for data center design, enabling customers to choose the most suitable dielectric fluid and cooling infrastructure based on their specific needs, budget, and environmental considerations, without concerns about heat exchanger compatibility. |

Optional All Stainless Steel Models

In certain immersion cooling applications, particularly those with extremely high demands for coolant purity, such as in high-performance computing (HPC) or specific chemical process cooling, any minute release of metal ions into the coolant can negatively impact system performance or fluid lifespan. Addressing such requirements, KAORI offers its S Series all-stainless steel brazed BPHEs. All plates and brazing materials that come into contact with the fluid are made from high-quality stainless steel, fundamentally eliminating the risk of copper ion release. This design ensures exceptionally high purity of the coolant, effectively extends the lifespan of the dielectric fluid, and mitigates potential equipment damage caused by chemical reactions. Simultaneously, it provides excellent corrosion resistance, offering customers a more secure and long-term operational guarantee.

High Heat Efficiency Design for System Volume ReductionOne of the advantages of immersion cooling systems is their high power density, which necessitates that their internal components possess extremely high heat exchange efficiency and a compact volume. KAORI BPHEs employ a unique corrugated plate design and precise brazing processes to maximize heat transfer area and fluid turbulence, ensuring extremely high heat transfer coefficients within a very small volume. For instance, the K200 model can provide up to 90kW of cooling capacity. This high heat efficiency design allows for a reduction in the overall volume of immersion CDU systems, saving valuable data center space and increasing cooling capacity per unit area. Concurrently, the compact design also reduces manufacturing costs and transportation complexity, providing customers with a more competitive overall solution. |  |

Passed Pressure and Lifetime Durability Tests

Immersion cooling environments can face variable pressure and temperature conditions, posing challenges to the long-term stability and reliability of heat exchangers. KAORI performs stringent quality control and durability tests on all its BPHE products to ensure they can withstand harsh operating conditions in real-world applications. These tests include burst pressure tests up to five times the design pressure , verifying the structural integrity of the product under extreme pressure; and rigorous lifetime tests, simulating performance during prolonged high-load operation to ensure durability. Through these comprehensive and strict tests, KAORI BPHE products demonstrate their excellent reliability and robust durability, providing stable and trouble-free thermal management performance even in long-term, high-load immersion cooling applications, significantly reducing data center operational risks and maintenance costs.