Feature ArticleBrazed Plate Heat Exchanger Applications in In-Row CDU

reads

As data centers evolve to meet higher efficiency and lower energy goals, liquid cooling has become increasingly prevalent.

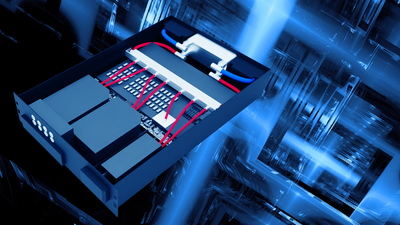

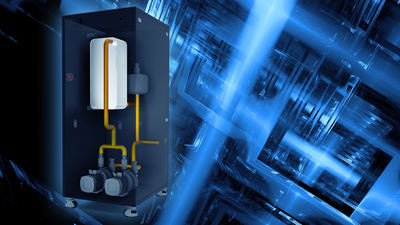

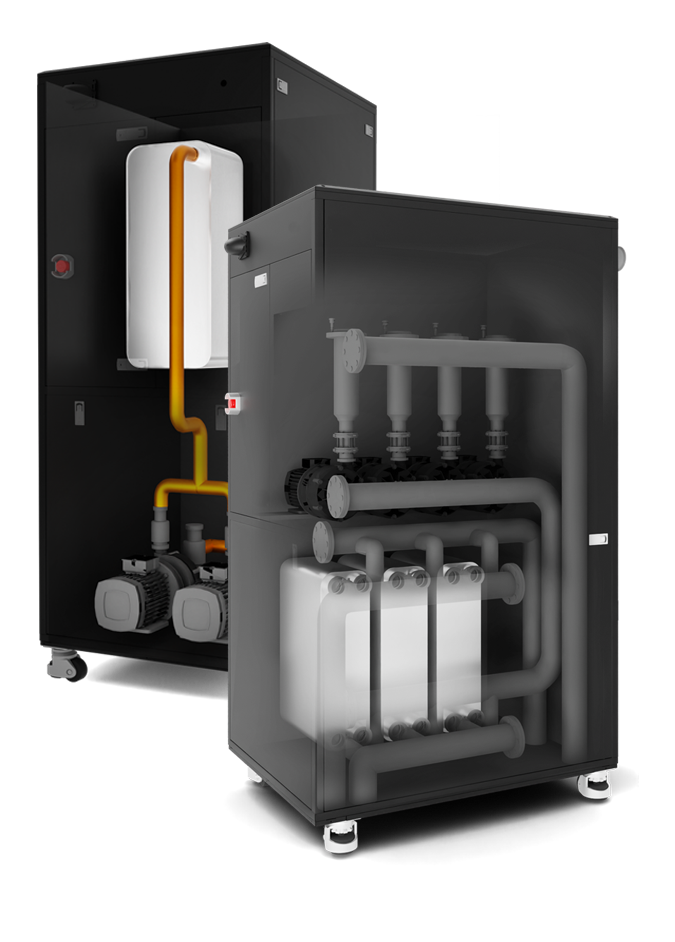

Introduction to In-Row CDU in Data CentersThe In-Row Cooling Distribution Unit (CDU) offers a smart and effective way to deliver cooling directly to high-density racks. Positioned between server cabinets, In-Row CDUs target the heat load at its source—making them a key component in hyperscale, HPC, and AI deployments. When paired with hot and cold aisle containment, this approach can significantly enhance cooling performance and energy savings. |  |

Brazed Plate Heat Exchanger Applications in In-Row CDU

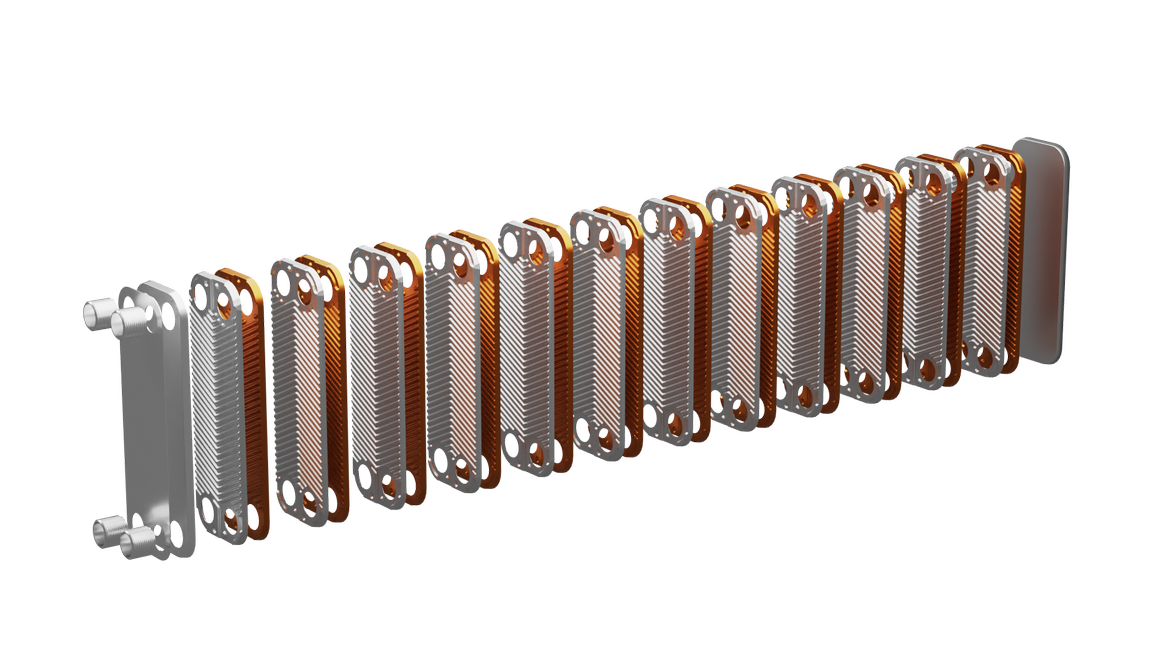

In In-Row CDU systems, the brazed plate heat exchanger (BPHE) plays a pivotal role in delivering efficient thermal management. KAORI’s BPHE is purpose-built for this application, supporting over 800 kW of cooling per unit and easily scalable through parallel installation for systems requiring over 3 MW of capacity. Known for its high performance, modular scalability, and integration flexibility, KAORI’s BPHE is a trusted choice for advanced data center infrastructure worldwide. The connectors and plates of KAORI's BPHE products are made of stainless steel, and 99.9% pure copper is used as the brazing material. Standard designs support up to 30 bar (up to 140 bar upon request) and a maximum working temperature of 200 °C , and are certified by CE(PED) / UL.

Excellent Heat Dissipation Performance and Robust DesignIn-Row CDUs, as core cooling equipment in data centers, must handle thermal loads from multiple high-density racks, thus requiring extremely high heat dissipation efficiency and long-term reliability from heat exchangers. KAORI BPHEs employ an innovative plate design and precise brazing techniques to maximize heat transfer area and fluid turbulence, ensuring exceptionally high heat exchange efficiency, capable of effectively transferring up to megawatts of heat. Furthermore, every KAORI product undergoes stringent quality control and testing, including burst pressure tests and demanding lifetime tests, far exceeding industry standards. This effectively withstands system pressure fluctuations and thermal stress, ensuring that BPHEs maintain excellent performance and durability during prolonged, high-load operation, significantly reducing data center operational risks. |

Tailored SolutionsKAORI deeply understands that every data center's cooling needs are unique, and customized solutions can bring significant efficiency improvements, especially in large-scale In-Row CDU deployments. For In-Row CDU applications, KAORI possesses extensive experience and a professional engineering team capable of providing diverse customized BPHE solutions based on specific customer factors such as thermal load (ranging from 800kW to 2.5MW), space constraints, fluid type, and budget. This includes not only the selection of standard models but also optimized designs for specific performance indicators and system integration requirements, such as size, flow configuration, and connector types, ensuring that the provided heat exchangers perfectly match the customer's In-Row CDU system to achieve optimal heat dissipation performance and operational efficiency, effectively meeting the stringent requirements for centralized cooling in high-density computing like AI/HPC.Complete In-House Design and ProductionAs a leading global manufacturer of brazed plate heat exchangers, KAORI possesses a complete in-house process from product concept, design, and R&D to final production. This means we maintain strict quality control and oversight at every stage, ensuring that the BPHE products delivered to customers meet the highest quality standards and consistency. Complete in-house manufacturing capability allows KAORI to precisely control production costs and rapidly respond to market changes, shortening product development cycles. For In-Row CDU applications, which demand high customization and stable supply, KAORI's comprehensive production capability serves as a solid foundation for customers to build reliable and high-performance data center infrastructure, ensuring product quality and stability, thereby reducing long-term operational risks for clients. |  |

Professional Technical Team and Market Reputation

Choosing KAORI means choosing a partner with decades of profound experience in the heat exchanger field. We have a professional research and development team that continuously invests in innovation, constantly launching advanced liquid cooling solutions that align with market trends. KAORI products are widely acclaimed in the global market, having established a long-standing and excellent reputation in the industry based on their outstanding performance, reliable quality, and comprehensive after-sales service. Whether it's product selection, system integration, or after-sales support, KAORI can provide professional technical consultation and assistance, ensuring the stable and efficient operation of customers' In-Row CDU systems. This professional technical support capability and broad market recognition provide customers with a worry-free partnership experience, ensuring the long-term stability and efficient operation of their data center infrastructure.

Explore KAORI Solutions

Recommended Models

Z Series - Large Diagonal BPHE