Feature ArticleCommon Reasons for Damages in BPHEs- (1) Scaling

reads

Brazed plate heat exchanger is formed with chevron plates and vacuum brazed with copper, it contains very compact and special structure. Two fluids can perform high efficiency heat exchange with very little temperature difference, it is also corrosion resistant, pressure resistant, compact, high efficient. It is widely used in HVAC, hydraulic cooling, heat recovery…ect, and acting as a very important role in energy saving and carbon emission reduction in major industries.

Brazed plate heat exchanger normally has long lifetime under suitable working conditions, however we still need to be cautious about the followings that may cause rare damages. Kaori’s BPHE team has more than 30 years of experience in helping system designers and users to use BPHE properly, so the lifetime is maximized, making it economical and satisfactory for customers.

Scaling

Common Characteristics

- Scaling normally appears on the water side of heat pump and chiller (especially open loop water circuit), scales build up overtime (from months to years)

- Common early phenomenon: Performance drop, high pressure loss on water side, increase in temperature difference between water inlet and outlet, and decrease in water flow,.

- Other phenomenon: Abnormal in refrigerant system (Shut down due to high pressure, or increase the discharge temperature), internal leakage due to corrosion, deformation.

Common Cause

- Grease within water, water hardness (>8.5°dH), microorganism, lack of CIP cleaning maintenance (this is commonly ignored when filter is being installed)

- Scaling by inorganic salt, this is more common in 45℃ and above heat pumps, desuperheater and heat recovery…etc.

- The choice of cleaning liquid also has contribution to scaling: CaSO4 and CaCO3 are different in properties, CaSO4 is not a good choice for scaling caused by grease or microorganism

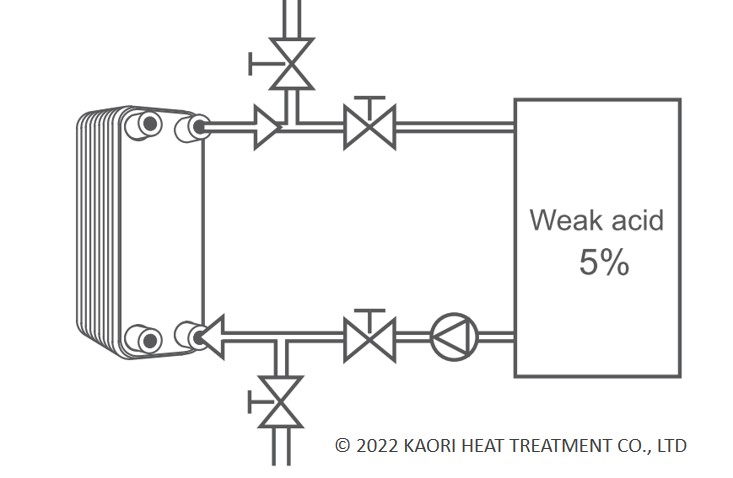

Kaori's Recommendation for Back Flushing Cleaning Procedure

Back flush with weak acid (under 5% of oxalic acid or citric acid), this will remove large amount of scale, but remember to clean with large amount of fresh water afterwards to prevent acid residue.