Feature ArticleKAORI Ultra High Pressure Heat Exchanger Prefect Solution to Expand Your CO2 Systems Portfolio with C Series

reads

Using CO2 in a wide range of applications around the world and it is exciting to note the rapid rate at which transcritical CO2 refrigeration installations are increasing globally. According to the shecco’s Market Development researchers estimated the number of system installations to be more than 35,500 today. This is a dramatic increase from the 140 installations counted in 2008 (all of which were in Europe). This growth is most noticeable within regions such as Europe, the U.S., Canada, Japan, Australia, New Zealand, and South Africa.

KAORI has been developed Ultra High Pressure Heat Exchanger C Series for various CO2 applications over 12 years. Specially designed for the gas cooler, condenser, evaporator and economizer in R744 (CO2) heat pump and refrigeration system. We can offer maximum working pressure 70 bar, 100 bar and 140 bar, with its muscular structure capable of handling working pressure up to 140 bar for BOTH sides.

The quality and the durability of C series is proved inspection, achieving the burst test pressure up to 700 bar and cycle test over 100,000 cycles.

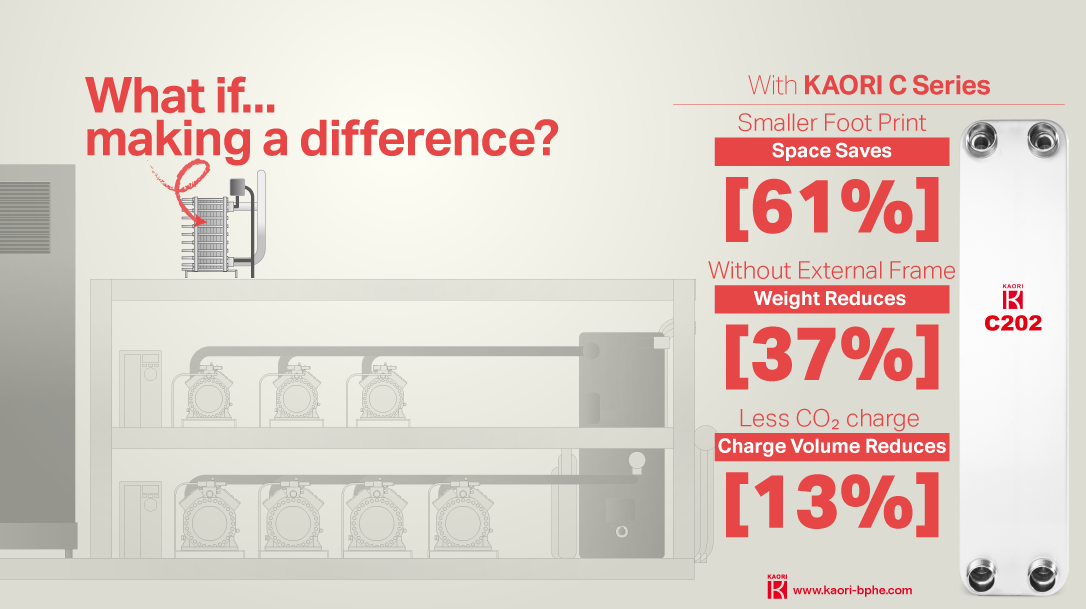

With Kaori C202, three key benefits for your CO2 System are frameless design, which we reduce 37% weight of product, outstanding heat transfer performance and low pressure drop. More than that, we can deliver full range to expand your CO2 system portfolio.

“We have used Kaori C series for more than three years, which help our CO2 system achieve greater reliability, availability and efficiency. This is the extremely durable components that I have been used ever. By leading CO2 Heat Pump manufacturer in the east Asia.”

More and more perfect solution for #Transcritical and #Subcritical CO2 Supermarket, Commercial & Industrial Refrigeration as following,

1. CO2 compressor racks (#Booster / #Cascade)

2. CO2 condensing units

3. Plug-in units( water loop type) for display cases CO2 system

3.1 Water cooled gas cooler

3.2 Suction line/gas heat exchanger

3.3 Subcooler

3.4 Evaporator

3.5 Heat Recovery for district heating

3.6 Flash gas heat exchanger

3.7 Oil Cooler