Feature ArticleUtilization of BPHE in clean hydrogen industry

reads

Green Hydrogen Industries

Generation and Application of Green Hydrogen

Green Hydrogen Generation

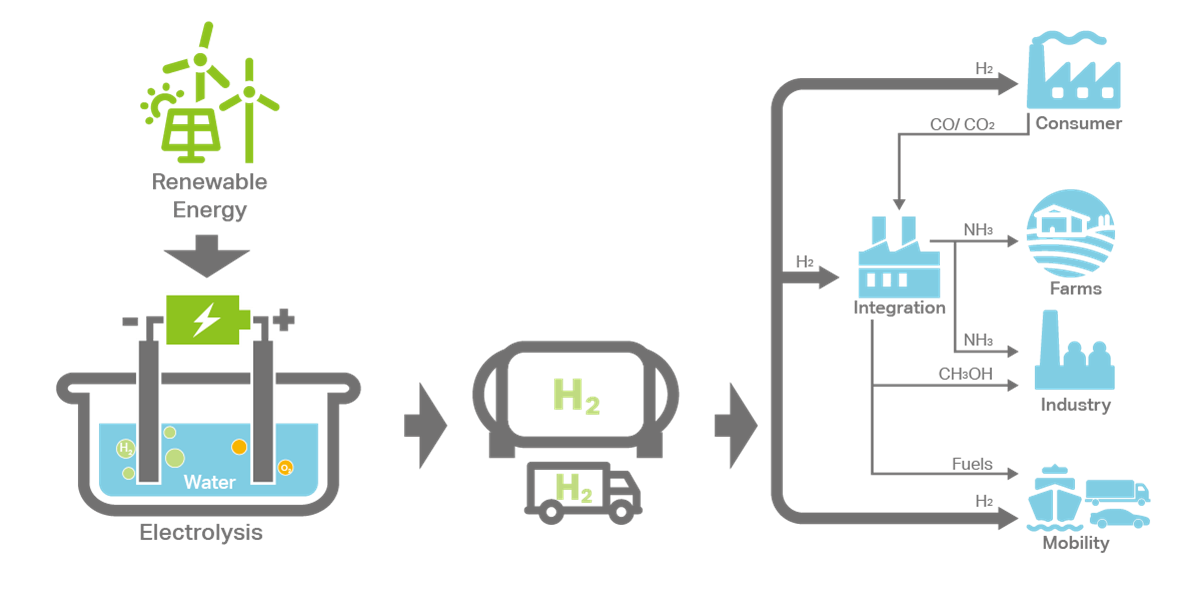

Green hydrogen (Green H2) means hydrogen generated from renewable energy (wind, solar, or hydro power), it has zero carbon emission, and is environmental friendly. The most common method to generate hydrogen is water electrolysis, meaning separating hydrogen and oxygen through chemical reaction.

How to Utilize Green Hydrogen

Green hydrogen is a clean energy that can be utilized in many fields, it replaces fossil fuel, reduces carbon emission and environmental impact. Green hydrogen can be used in the production of chemical products, raw materials, supply power and heating to fuel cell battery. Green hydrogen can even be the direct fuel source for aviation, marine vessel, automobile, and heavy transportation.

Kaori’s BPHE in Green Energy Industry

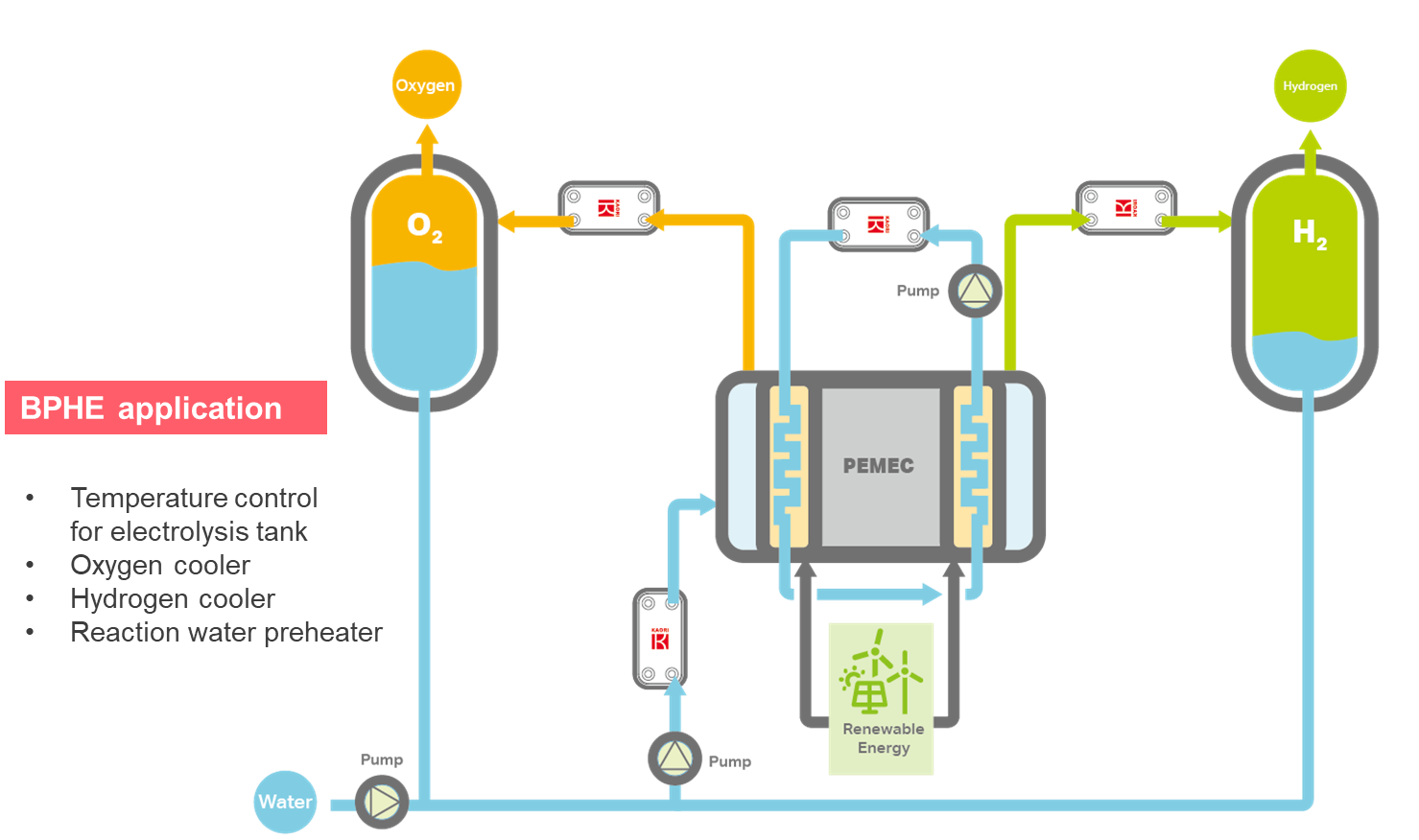

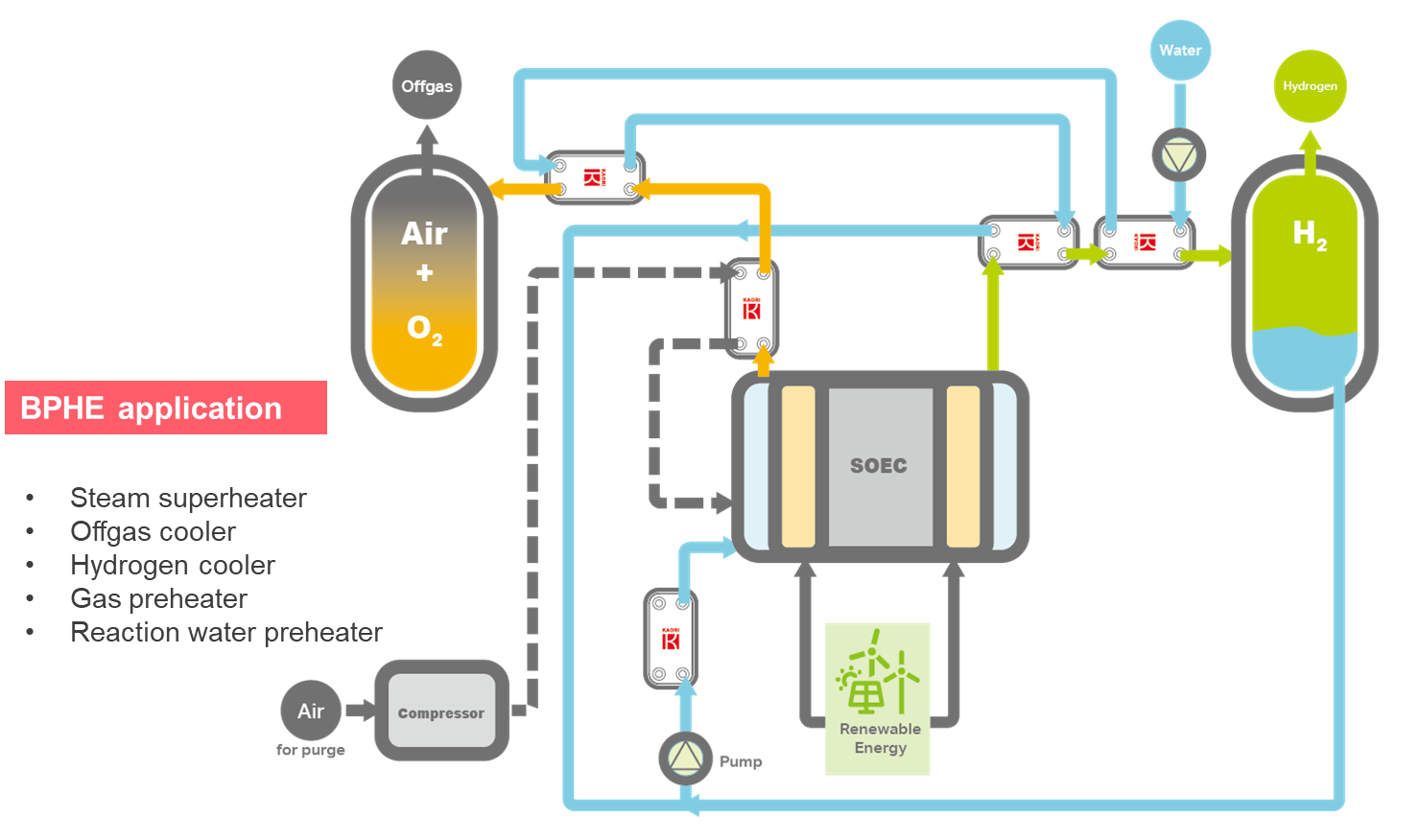

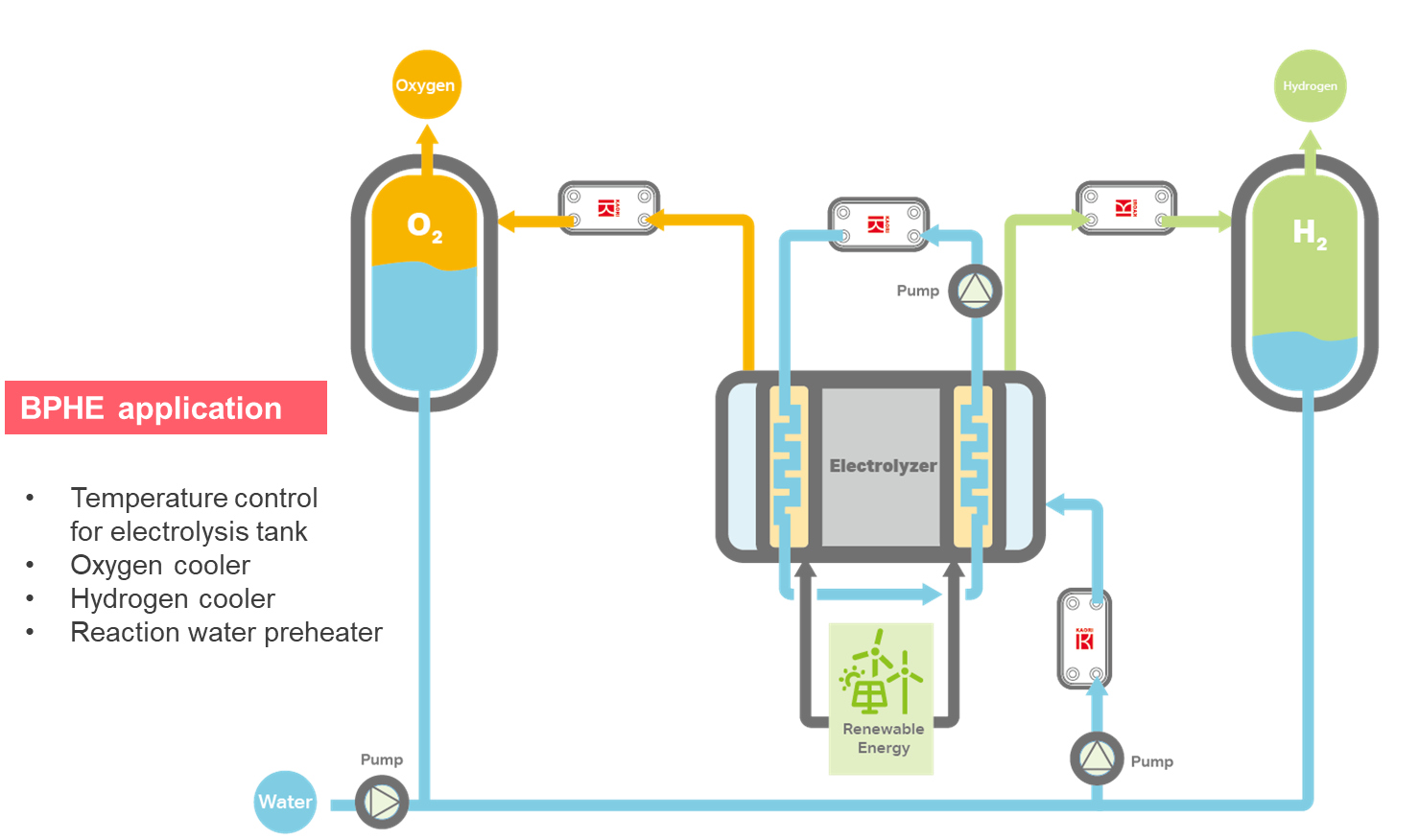

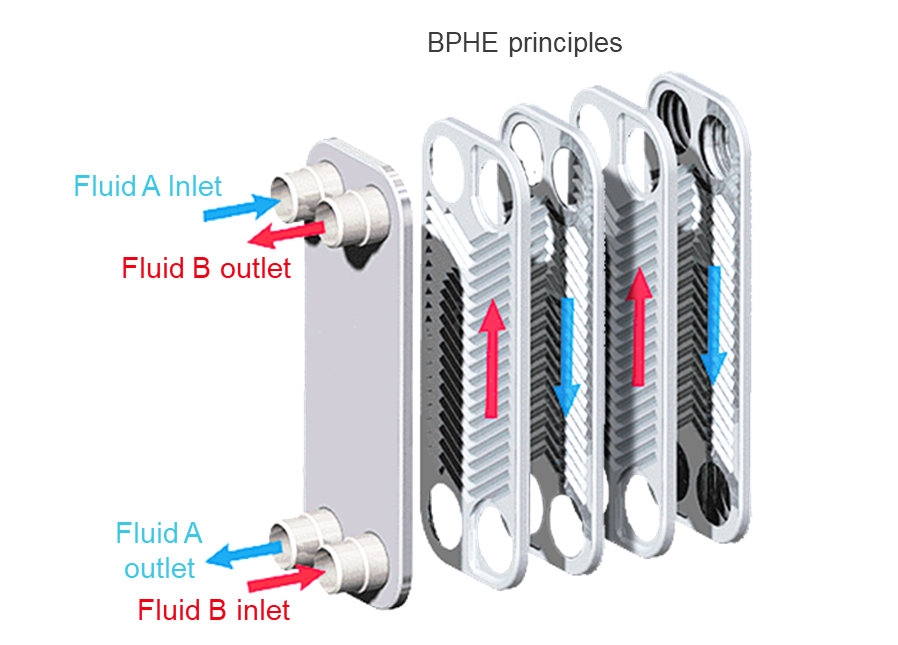

Regardless of PEMEC(Proton-exchange Membrane Electrolyser Cell), AEMEC(Anion Exchange Membrane Electrolyser Cell), AEL(Alkaline Electrolyser), SOEC(Solid Oxide Electrolyser Cell) or any other electrolysis technologies, Kaori can provide high value solutions. Kaori’s brazed plate heat exchanger provides solutions to electrolysis equipment, electrolyte, cooling of working fluids, and system heat recovery.

Kaori’s products can be utilized in the heating and cooling of hydrogen generation. Kaori also possesses many years of experience in fuel cell development, hydrogen generation, and industrial equipment. With the capabilities we possess, we can support clients in the system development of hydrogen energy and related technology.

Kaori’s Various BPHE Products

High Nickel Alloy Products

Utilizing special materials, making it the leader in high temperature SOEC/ SOFC applications, capable of handling temperatures up to 900°C.

All Stainless Steel Products NEW RELEASED

Using stainless steel as the brazing filler, suitable of PEM electrolysis hydrogen generation and power system, or deionized water with low conductivity that does not allow copper ion.

Kaori’s BPHE for PEMEC

Kaori’s BPHE for SOEC

Kaori’s BPHE for AEMEC/ AEL

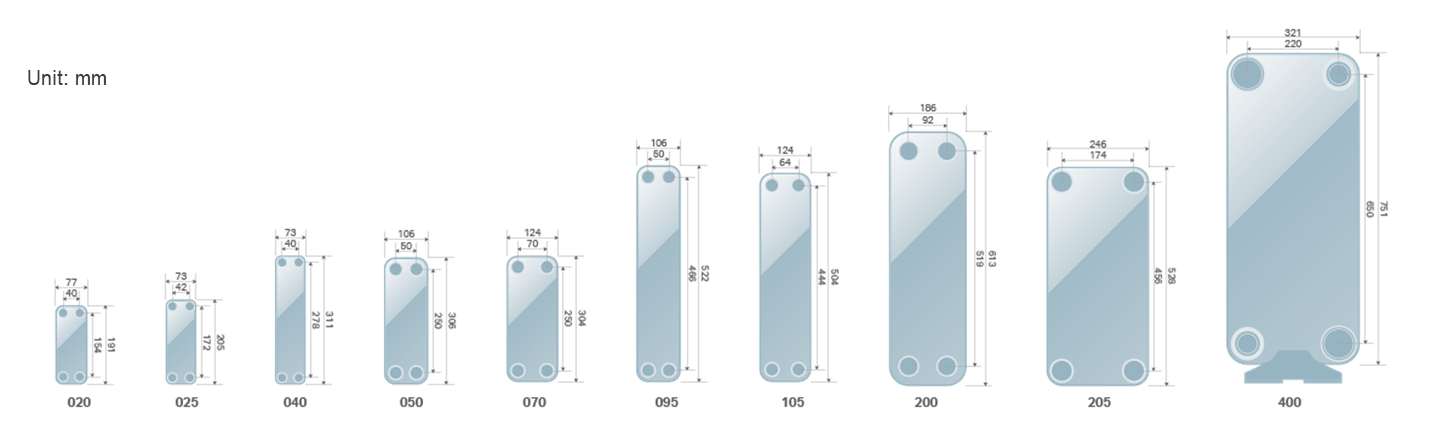

BPHE models for PEMEC/ AEMEC/ AEL

Brazing mode | ALL STAINLESS STEEL BPHE | |

Model | K025, K040, K050, K070, K095, K105, K200, K205, Z400 | C020, C040, C095, C200 |

Plate material | SUS316 | SUS316 |

Brazing material | SUS Alloy | SUS Alloy |

Max. working pressure (bar) | Up to 10 | Up to 30 |

Max. working temperature (°C) | 200 | 200 |

* For other working pressure or temperature request, please contact Kaori representative.

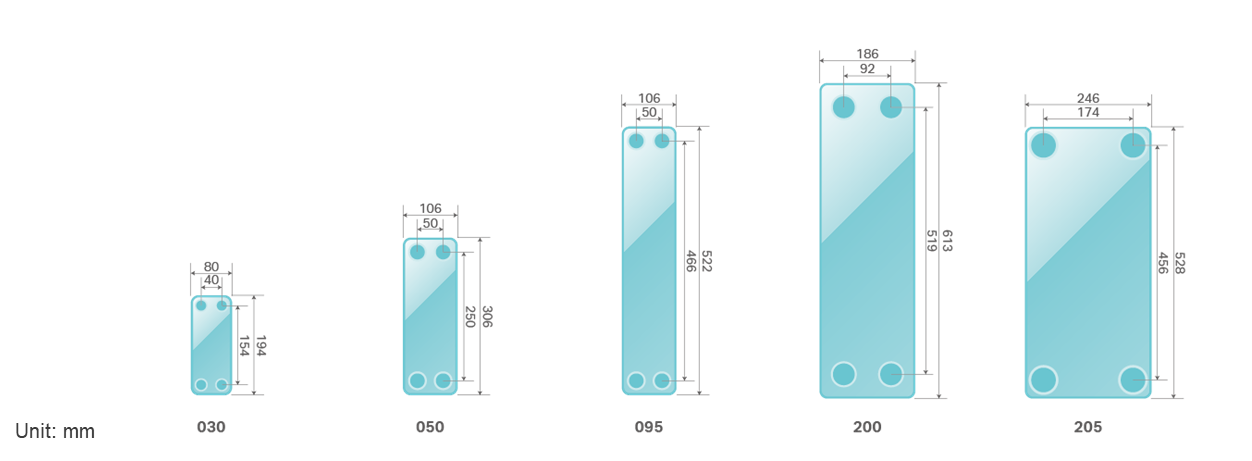

BPHE models for SOEC

Brazing mode | Hi-Nickel BPHE |

Models | H030, H050, H095, H200, H205 |

Plate materials | Nickel-based alloy |

Brazing materials | Nickel-based alloy |

Max. working pressure (bar) | 2 to 10 |

Max. working temperature (°C) | Up to 900 |

* For other working pressure or temperature request, please contact Kaori representative.